Clean and Disinfect TEE Ultrasound Probes in One Device!

One Device ... Clean and disinfect TEE Ultrasound Probes

The TEEClean Automated Cleaner Disinfector when used with TD-5 or TD-8 high-level disinfectant and TEEZyme enzymatic cleaning agent has an industry-, leading, proven track record of compliance. TEEClean has been available for use by healthcare professionals for 3 years with absolutely zero reportable incidents to the FDA. Confidence can be assured with the TEEClean automated cleaner disinfector that your compliance to standards and guidelines for the reprocessing of TEE probes is actively and effectively met.

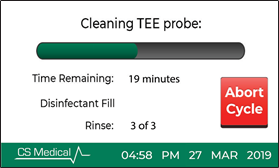

TEEClean was designed to comply with all recommendations and guidance available for proper reprocessing of TEE probes by manufacturers, industry experts, and occupational health and safety regulations. TEEClean gives clear and easy prompts through a 7-inch LCD screen to walk the end user through proper operation and ensure a successful cleaning and high level disinfection of a soiled TEE probe. Unlike manual cleaning and soaking and other devices designed for similar purposes, TEEClean removes several human interactions that can potentially lead to a TEE probe not being properly cleaned or high-level disinfected or occupational exposure to high level disinfectants and neutralizers. The reduction in handling also has shown to reduce probe damage which in many instances is a high-cost center for healthcare institutions. Could a few less damaged TEE probes pay for a TEEClean?

By using a high-level disinfectant that is single use, the healthcare professional is not required to use chemical indicator test strips. Thus, TD-5 and TD-8 require no MRC (Minimum Required Concentration) validation. The CS Medical 500 ml container of disinfectant eliminates the need for end user confirmation of the test strip as well as the subjective reading of the test strip. Chemical test strips can be very problematic and costly. When reviewing reusable chemistries, you must consider the cost and shelf life of the test strips. These test strips are not universal to all chemistries used in reprocessing suites; they are specific to the proprietary formulation of the manufacturer. The use of chemical test strips to validate MRC is an area where risk should be reviewed and a determination of best practices through staff training and employee testing should be incorporated.

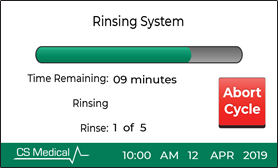

TEEClean achieves high-level disinfection of a TEE probe in 5 minutes. As with any device, the residue of the disinfectant must be properly removed to prevent staff or patient contact. Some disinfectants, if not properly rinsed from the probe, can lead to a chemical staining of the skin or esophagus known as "black mouth". This is only present with the use of OPA as the high-level disinfectant and if residue is not properly removed. Due to TEEClean's extensive rinse cycles and toxicological validation, black mouth is never an issue.

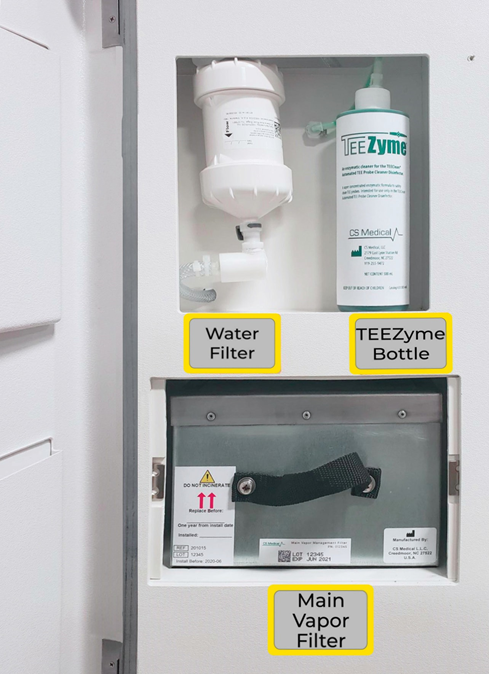

Occupational exposure is another concern that TEEClean eliminates as it was designed to meet the ANSI/AAMI ST58 standard. TEEClean acts just like a ductless filtered chemical hood. TEEClean has an independent filtration system that effectively captures and neutralizes vapors that are generated during the high-level disinfection process. The activated bonded carbon filter effectively removes Glutaraldehyde or OPA vapors while the overall design of the TEEClean mitigates occupational exposure through negative pressure airflow within the cleaning and disinfectant's reservoir.

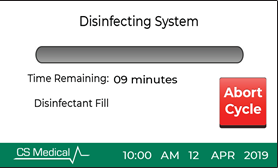

How does TEEClean provide high-level disinfection in only 5 minutes? Through microprocessor controls TEEClean drives internal components that heat up and circulate the disinfectant solution within the device. By adding heat and maintaining constant flow of the disinfectant, the TEE probe is in contact with the chemical, at the correct temperature, for only 5 minutes. TEEClean ensures both contact time and temperature as these elements are critical in achieving high-level disinfection. If either of these elements are missing, then TEEClean reports an error and states that the TEE probe has not been properly high-level disinfected.

The problem with other systems is that the high-level disinfectant is placed on a hot plate and allowed to stagnate when not in use. Additionally, these systems pump the stagnant disinfectant into the disinfection reservoir and allow it to sit and cool during the soaking phase of the process. A point of concern, since the solution is not circulated, is whether the entire volume of the container has achieved an equal temperature or if one might find warmer or cooler portions of the liquid disinfectant. Once the solution has been pumped into the soaking tubes, a thermal decrease of the disinfection solution must be present. Another factor to the solution being held stagnant is the environment in which the device is operating. Areas within the healthcare facility that operate at 65-72°F are more likely to cool the disinfectant more quickly than areas that operate in the 70-76°F range. Many reusable high-level disinfectants have a minimum contact temperature that ranges between 20-55° (60-131 °F), as stated on the label's indication for use. The proper contact time, at the proper contact temperature can range all the way from 5 to 45 minutes. Contact time and contact temperature are the two most critical factors to successful high-level disinfecting, regardless of the probe or instrument being reprocessed. A chemical test strip does not determine if the disinfectant is at the correct temperature, it only tells you if the potency of the solution is above the manufacturer's MRC established at the time of FDA clearance. Reliance on a test strip cannot be the sole method to ensure chemical efficacy; temperature is of vital importance in this process. All these risky variables are eliminated when reprocessing TEE probes with TEEClean.

Single-use disinfectants also play a major role in mitigating the risk of HAIs (Healthcare Acquired Infections) when compared to reusable disinfectants. Depending on the TEE probe's level of bedside cleaning, pre-cleaning, and the patient's medical condition, the gallon of reusable high-level disinfectant could become an incubator. It is widely published that reusable disinfectants are susceptible, as concentration weakens, to the potential of bacterial spores being viable and that the closed, warm environment present in the container fosters a potential hazard to the next probe to be reprocessed.

Contamination, or bioburden, is present in each reuse study and results indicate that the claim of 150 cycles of reuse in a 14-day period is simply misleading. A study conducted by Norman Bruckner, PhD, regarding Metricide OPA Plus™ and Cidex®OPA solutions show that, under ideal and controlled conditions, the maximum reuse life of either chemical is far less than in previous claims. Additionally, the overall useful life is well shorter than the 14 days stated on the manufacturers' labels1• It is worth noting that three main factors affect the gradual reduction of the effectiveness of reusable high-level disinfectants. The decreased concentration is directly linked to the overall burden of microbes and organic matter. Depending on how well and when bedside cleaning and pre-cleaning are accomplished directly impacts how much burden is left on the TEE probe. A wet TEE probe is another factor as it adds to the overall volume of solution that, in turn, dilutes the disinfectant. If the TEE probe is not dried prior to insertion into the chemical or soaking tube, then the concentration is compromised. Finally, as the solution ages, it becomes more susceptible to bacterial spore growth. Solutions that are kept under constant heated temperatures are likely to age more rapidly than those allowed to elevate temperature on demand to perform the high-level disinfection process. For these reasons, CS Medical's single-use high-level disinfectants provide healthcare professionals with an effective strategy to reduce the potential of HAIs as it relates to the disinfection of TEE ultrasound probes.

A major concern to employee safety is exposure to high-level disinfectants. In all of CS Medical automated reprocessors, this exposure is eliminated. The high-level disinfectant container is opened inside the device under negative airflow that is filtered before release into the reprocessing suite. The container of TD-5 or TD-8 is completely rinsed free of any chemical residue and, at the conclusion of the disinfection and rinse cycle, can be removed and thrown away as general waste or recycling with no special disposal requirement. This is very different from the requirements by some automated devices that incorporate reuse chemistry in their designs. The healthcare end user is required to remove the bottle from the device, remove part of the fluid system, and then add a neutralization formula to the container prior to disposal. Furthermore, the new gallon of high-level disinfectant is placed beside the old bottle and the fluid system pieces is placed from the expired high-level disinfectant bottle into the new high-level disinfectant bottle. This presents two elements of risk. The first risk is exposure of the healthcare end user to the disinfectant. This risk will vary depending on the type of disinfectant and the temperature of the disinfectant. If the disinfectant is an aldehyde-based chemical, the neutralization agent can cause significant foaming and result in the bottle overflowing, an added safety concern. The aldehyde-based chemical could also cause a "black-mouth" staining of the end users hands if even a drop is spilled or splashed. The second risk is dilution/contamination of the fresh disinfectant by the expired disinfectant. This is a risk, regardless of how much or how little is allowed to transfer from the fluid system. Reduced concentration is directly linked to dilution and bioburden challenge. You are starting the entire process at a disadvantage in this scenario. 4

TEEClean helps promote a scientific and orderly workflow within the reprocessing suite. As TEE probes arrive in the area, they must go through an evidence-based step-by-step method of cleaning, rinsing, electrical leakage testing, high-level disinfection, rinsing, and drying before reuse. Most reprocessing suites for TEE probes are smaller and have less room than those designed for endoscope and other surgical instrument reprocessing. Many healthcare facilities prefer to have the reprocessing suite near the point of use for TEE probes due to the high cost and delicate nature of the TEE probe. A single probe can enter the reprocessing suite and be placed directly into TEEClean. The probe should be electrical leakage tested and this can be accomplished directly inside TEEClean with the results documented on both the printout and held within system memory for later recall. TEEClean allows you to simply your workflow, reduce handling, have confidence that the TEE probe is receiving an FDA cleared cleaning and high-level disinfection, and have all documentation ready to provide during an audit of how, when, and who completed the reprocessing of the soiled TEE probe.

Occupational exposure is a focal point in healthcare since it is the facility's responsibility to keep individuals healthy. The TEEClean, unlike other automated devices, utilizes a bonded carbon filter that not only adsorbs vapors, but neutralizes them. The filter is a solid block of activated coconut shell carbon. The design and bed depth of the carbon filter ensures successful capture of vapors and a long life. Similar devices utilize a blown carbon pellet type of filter that has poor performance when compared to that of the TEEClean's vapor management filter. Evaluation of vapor exposure risk to any high-level disinfectant should be considered prior to use. A well-engineered solution is one that ensures occupational safety from the vapors generated during the disinfection process and provides a reasonably long life before replacement.

TEEClean, as incorporated in the Complete Probe Reprocessing® suite of products, provides a systematic approach for the reprocessing of TEE probes. At the point of use, immediately after removal from the patient, the TEE probe should be treated with an enzymatic solution. This enzymatic treatment begins the breakdown of bioburden and reduces the potential for biofilm to form. TEEZyme® Sponge is an individually packaged, pre-saturated enzymatic applicator that allows the healthcare professional to effectively apply the enzymatic cleaner and add mechanical scrubbing action to remove bioburden and any foreign materials from the TEE probe's insertion shaft. Once the bedside cleaned TEE probe arrives it can be directly inserted into TEEClean, and the cleaning and disinfection cycle begins.

TEEClean and Complete Probe Reprocessing suite of products offer real risk mitigation for the reprocessing of TEE probes in today's healthcare setting. A TEEClean can give you confidence as you reprocess TEE probes and can ensure the reduction of HAIs in your facility. It could even save you money by reducing repairs due to excessive handling damage.

References:

1. (1) Bruckner, N., Ph.D. "Comparison of Metricide OPA Plus™ Solution and Cidex®OPA Solution

Use Properties", Oct. 2007, online at

https://docplayer.net/20778561-Comparison-of-metricide-opa-plus-solution-and-cidex-opa-solution-use

properties.html